vickers hardness test errors|vickers hardness test diagram : service Vickers hardness testing is vital in assessing critical parts' hardness and wear resistance, such as engine components, gears, and turbine blades. This ensures the reliability and safety of these components under extreme operating . So I got an email that looked suspicious.. hovered my mouse over the link to see the url.. and accidentally clicked on it and I flipped out! Luckily, when I submitted the email to notify the security team, I got a notification that it was a simulated phishing email! UGH but there have been a couple times where I have actually fallen for these .

{plog:ftitle_list}

WEBPrevisões de ténis grátis. Tenha acesso gratuito às mais recentes previsões e prognósticos de ténis, nas mais importantes competições realizadas pelo planeta. Acompanhe os campeonatos ATP e ITF, Masters 1000, Grand Slam e WTA, entre outros. A utilização dos nossos dados estatísticos é completamente gratuita e isso nunca mudará.

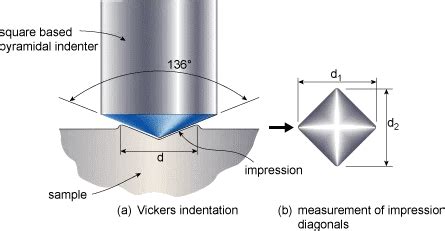

Vickers hardness testing is vital in assessing critical parts' hardness and wear resistance, such as engine components, gears, and turbine blades. This ensures the reliability and safety of these components under extreme operating .The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .Although most automated microhardness testing systems can automatically measure Vickers and Knoop impression repeatedly on finely prepared samples, many are fooled by surface .It was decided that the indenter shape should be capable of producing geometrically similar impressions, irrespective of size; the impression should have well-defined points of measurement; and the indenter should have high resistance to self-deformation. A diamond in the form of a square-based pyramid satisfied these conditions. It had been established that the ideal size of a Brinell impression .

vickers hardness testing procedure

vickers hardness testing machine price

The Vickers hardness test at a glance: Ideal for micro hardness testing. Can be used for case hardness depth measurement, Jominy testing and hardness testing of welds. Standards: ASTM E384, ISO 6507 and JIS Z 2244. See our .Vickers hardness testing has been widely used as one of the basic and reliable material test methods. Furthermore, triangular pyramidal indentation technique (the nanoindentation . What is the Vickers Hardness Test. NextGen explains the machine, its applications and the necessary consumables required for the Vickers Hardness Testing needs.

The issues of repeatability, accuracy and correlation are inherent to microhardness testing. However, by using properly maintained and calibrated equipment, trained personnel, and appropriate testing environments, testing .

The Vickers hardness test utilizes a pyramidal diamond in-denter to create an indentation on the material‘s surface. The diagonals (x and y axis) of the indentation are measured, and the . Vickers Microhardness testers creates measurements by using dead weights to create force. These light loading devices (10-2,000 gf) stack the dead weights directly on top of . The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard .

s9 plus vs s8 active drop test

vickers hardness testing machine diagram

s9 screen drop test

The Vickers hardness test method, otherwise called a microhardness test method, is used for small objects, thin sections, as well as the case depth work. + 86 755 61301520 [email protected] Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Microhardness test procedure, ASTM E-384, specifies a range of light loads .The Vickers hardness test operates on similar principles to the Brinell test, the major difference being the use of a square based pyramidal diamond indentor rather than a hardened steel ball. . Errors in Hardness Testing. There are many factors that can affect the accuracy of the hardness test. Some of these such as flatness and surface . In the Vickers hardness measurement, the combined uncertainty associated with the hardness value takes into account the relative uncertainties of diagonal length (d), the test force values (F) and other parameters like uncertainties in the indenter geometry, the indentation measuring system, etc., which are accounted in the CMC of the machine .

Gong J., Wu J., Guan Z., Examination of indentation size effect in low-load Vickers hardness testing of ceramics, Journal of European Ceramic Society, 1999, 19(15) 2625-2631. [4] Peng Z., Gong J., One the description of indentation size effect in hardness testing for ceramics, Journal of European Ceramic Society, 2004, 24(8) 2193-2201. [5]

The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. . This limit is set to avoid errors introduced by the deformation of the .Vickers hardness testing is commonly employed as part of quality control processes in industries where material reliability and consistency are critical. Vickers hardness test can contribute to material certification, compliance with industry standards, and ensuring the integrity of manufactured products.The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .

Barbato and Desogus ISO 146-1984. Metallic materials - Hardness test - Verification of Vickers hardness testing machines HV O, 2 to HV 100. ISO 640-1984. Metallic materials - Hardness test - Calibration of standardized blocks to be used for Vickers hardness testing machines HV 0, 2 to HV 100. ISO/DP 4546. Verification of microhardness testing .In contrast, 'Macro' Vickers loads vary from 1 to 120 kg. The indentations should be as large as possible, within the confines of sample geometry, to minimize errors in measuring the indentation (hence the reported hardness). Vickers hardness is also sometimes called Diamond Pyramid Hardness (DPH) owing to the shape of the indenter.In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. . There could be measuring errors due to the use of optical instruments. Surface imperfections can interfere with the test result if the surface is not prepared thoroughly. . Vickers Hardness (HV .

vickers hardness testing formula

The Vickers method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6507, ASTM E92, ASTM E384).

In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F[N]), the indentation on the sample is measured using a microscope.

The Vickers hardness test, an offshoot of the venerable Brinell test, has been used since the early 1920s. Although the concept of using one test method to cover a wide range of materials hasn’t changed much in the last 90 .

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test .Hardness testing according to current standards. Our hardness testing machines support a wide load range for the Vickers, Brinell and Knoop test methods. All methods are covered with the ISO 6506 / ASTM E10, ISO 6507 / ASTM E384, ASTM E92 and ISO 45452 standards. With the option to extend the load range from 0.25 g to 10 g, we surpass the .

The Knoop test is conducted in the same manner, and with the same tester, as the Vickers test. However, only the long diagonal is measured, except for the projected area hardness (PAH) test recommended by Blau. This, of course, saves some time. The Knoop hardness is calculated from HK = 14229L / d 2 The Leeb Hardness Test, also known as the rebound hardness test, measures hardness by analyzing the rebound of an indenter, rather than the size of an indentation. It is portable and ideal for on-site testing of large and heavy components, offering a non-destructive method that causes minimal damage to finished parts and coatings.

The Wilson VH1150 Macro Vickers Hardness Tester is the ultimate macro-Vickers hardness tester. Boasting a unique load range of 300gf – 50kgf, enjoy its user-friendly operation with automatic load selection and a seamlessly integrated motorized turret in .

s9 silicone case drop test

Effect of the variation of the mean indentation diagonal, for different values of d , on the relative uncertainty of Vickers hardness. The green, black and magenta lines represent the size of the .The Wilson® VH1150 Vickers Series Hardness Testers offer a versatile and user friendly solution for a wide range of hardness scale testing. For single scale hardness testing, the Wilson VH1150 Tester is equipped with a five-position turret which includes one indent-er position as well as a 10x and 20x objective.

Vickers-Armstrong Ltda., the test method has become popu-lar as Vickers hardness. Vickers hardness tests can be used in many applications, as in mechanical components industry, surface treatments, glasses and laminates, being also present in laboratories and universities with applications in several kinds of materials

In the use of hardness test blocks, the uncertainty due to block non-uniformity can be reduced if one is willing to make measurements at specified locations on Hardness testing is thought to be one of the easiest tests to perform on the shop floor (Figure 1) or in the metallurgical laboratory (Figure 2) but it can be one of the hardest tests to do properly. . and microhardness tests (e.g. Vickers, Knoop). The Brinell test is used primarily for testing forgings and castings, particularly cast iron .Vickers number 1 2 Average 1 0 0 0 312. 2 0 0 0 315. 3 0 0 0 317. 4 0 0 0 292. ANALYSIS Hardness Value: A measurement of the material's hardness is provided by the test's Vickers hardness number. Greater hardness is indicated by a higher HV. Vickers hardness values are a useful tool for comparing the hardness of various materials .

WEB2ª via de fatura por e-mail. Receba a 2ª via da sua fatura por e-mail. Recomendações de Uso do Cartão. Como usar o seu cartão, dicas de segurança e muito mais. Atendimento Cartões CAIXA. Telefones da CAIXA. Contrato. Leia o contrato na íntegra (também disponível em áudio) Formulário de contestação. Baixe aqui. Tabela de Tarifas

vickers hardness test errors|vickers hardness test diagram